Plastic vs Metal Enclosures: When Plastic is the Smart Choice

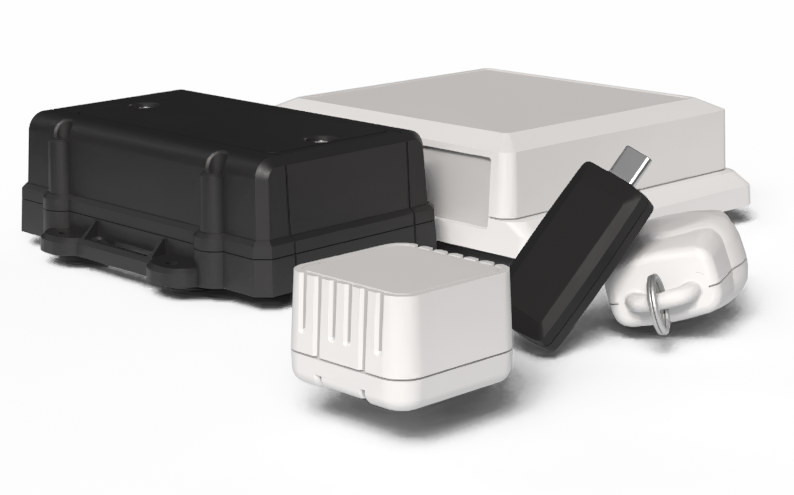

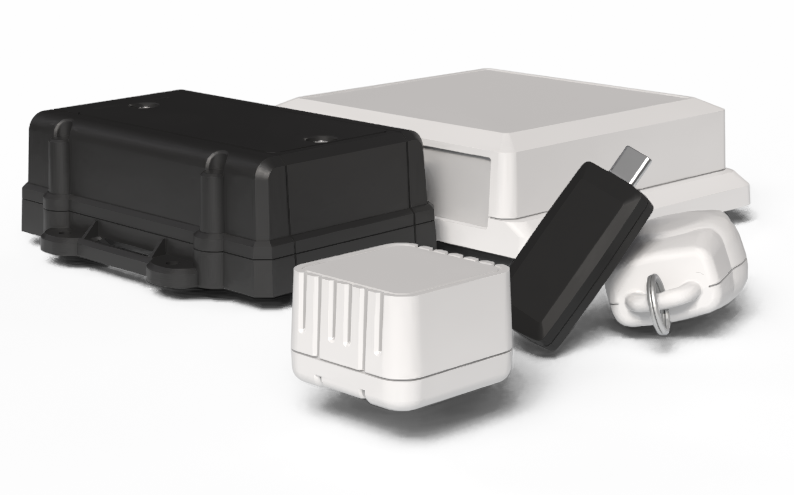

When deciding between plastic and metal enclosures for electronic components, the debate often comes down to performance, cost, and durability. In the world of electronics, plastic enclosures have emerged as a popular option, offering a host of benefits that frequently outweigh those of their metal counterparts. This article explores the advantages of plastic enclosures over metal ones, providing insights into why they’re often the preferred choice in various industries.

1. Cost-Effectiveness That Drives Savings

One of the standout advantages in the plastic vs metal enclosures discussion is cost. Plastic enclosures are typically more affordable due to the efficiency of manufacturing processes like injection molding. This method not only streamlines production but also minimizes material waste and labor costs. As a result, companies benefit from reduced expenses, especially when producing large quantities, making plastic enclosures a budget-friendly option for both startups and established enterprises.

2. Lightweight Design for Enhanced Portability

Another significant benefit of plastic enclosures is their lightweight nature. Plastic materials have a lower density compared to metals, which means devices are easier to handle and transport. This reduction in weight can lead to lower shipping costs and improved portability—key factors for products like handheld gadgets and portable equipment. In the plastic vs metal enclosures debate, the lighter weight of plastic is a crucial advantage for applications where mobility and ease of installation are paramount.

3. Superior Corrosion Resistance for Longevity

Environmental exposure is a major concern in many electronic applications. Metal enclosures, while sturdy, are prone to corrosion when exposed to moisture, chemicals, or extreme weather conditions. In contrast, high-quality plastics (such as polycarbonate and ABS) offer excellent resistance to rust and degradation. This corrosion resistance ensures that electronic devices housed in plastic enclosures remain durable and reliable over time, even in harsh environments like industrial settings, outdoor installations, or marine applications.

4. Enhanced Electrical Insulation for Safety

Electrical insulation is critical when protecting sensitive electronic components. Plastic enclosures naturally provide superior insulating properties, reducing the risk of electrical interference and accidental short-circuiting. Unlike metal enclosures, which can conduct electricity and potentially compromise device safety, plastic enclosures help maintain signal integrity by effectively isolating internal circuitry from external electromagnetic interference (EMI). This quality is particularly beneficial in applications where safety and performance are non-negotiable.

Conclusion

In the ongoing debate of plastic vs metal enclosures, plastic clearly stands out with its compelling advantages. Its cost-effectiveness, lightweight construction, exceptional corrosion resistance, and superior electrical insulation make plastic enclosures the go-to solution for housing electronic components in a diverse range of applications. As industries continue to push the envelope with innovative designs and technologies, the preference for plastic enclosures is set to grow, ensuring that devices are not only reliable and safe but also economically viable.

By understanding these key benefits, engineers and product designers can make more informed decisions when selecting the best enclosure for their electronic devices—often finding that plastic offers the perfect blend of performance, durability, and affordability.